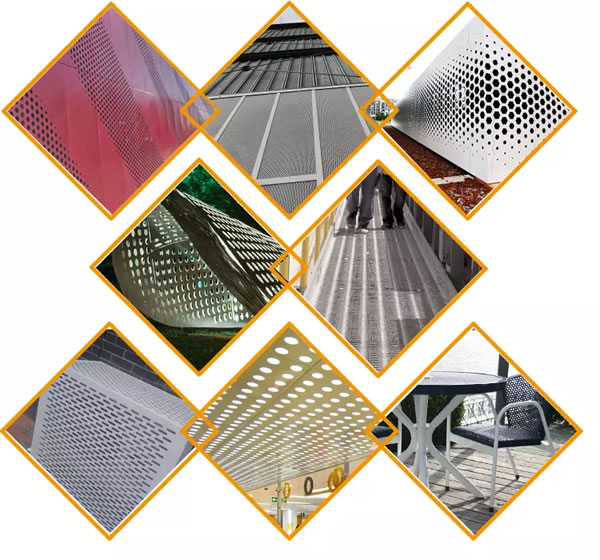

Architectural and Ornamental Perforated Metals

Perforated sheets function as architectural products for decoration, security, diffusers, ventilation, acoustic control, space separation:

Privacy screen;

Roof and wall panels;

Space dividing / partition curtain walls;

Sun shading screen;

Vent screen;

Wind screen.

Features of perforated screen:

» Easy to process

»Multi choice of surface treatment

» Easy to fix

» Various thickness, aperture shape and opening design

» Good strength

» Light weight

» Long time service

» Precise size

Available Materials: Stainless steel, aluminum, steel sheet, copper sheet, nickel, titanium, and so on.

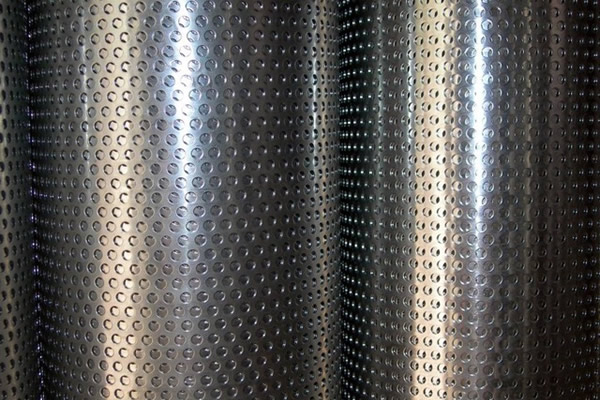

Perforated Stainless Steel

We manufacture a wide range of decorative perforated metal ss panels.

Thickness: 0.1mm-2.5mm

Width: Max 1200mm

Standard sheet size:1000mm*2000mm

Hole arrangement type:

1) 60° staggered round hole;

2) 45° staggered, round hole;

3) Vertical;

4) Square hole;

5) Long hole(vertical);

6) Hexagonal hole;

Opening area

Open area is the total area of the holes divided by the total area of the sheet and is expressed as a percent.

The higher the open area, the more material distortion takes place, especially when the decorative perforated metal panels is bordered by margins on all four sides.

Process:

Stamping, leveling, cutting, bending, reeling, welding, shaping and surface treatment.

Characteristics:

Stainless steel perforated mesh is winding resistant, ageing resistant and corrosion resistant.

Perforated Brass / Copper / Phosphor Bronze

Perforated copper cladding with a range of perforation patterns can be used to create unlimited decorative effects. Brass and bronze are also popular with architects.

Perforated Aluminum

We produce a variety of precision stamping aluminum mesh. The thickness of sheet that can be pressing is 0.1-12mm.

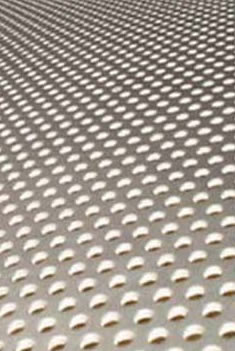

Round Hole Aluminum Sheet

Aluminum Perforated Panels with Staggered Round Hole Design

Decorative aluminum 3/16 "

Applications:

Perforated metal is perfect for ventilation, floor tread, protection and decoration. Used popularly as architectural facade, acoustic control ceiling and wall covering curtain, security screens, air-condition units, radiator covers, screening, display units and so on.

Perforated Metal Flooring

Made from heavy-duty steel perforated sheet, the embossed surface plays the role of anti-skid. This product can be used for industrial corridor, automotive assembly line, stairs, platforms, floor laying, also for a variety of corrosive environments with long service life.

The perforated round hole pattern is our most popular style, but it is also available in raised and slotted holes.

Perforated Panels for Indoor and Outdoor Decoration

Outdoor decorative metal mesh products can be used for decorating the external walls of the building; highway, railway, subway and other transportation services and facilities; architectural mesh, walls decoration, generator room, factory buildings, and sound-absorbing panels.

Material: Stainless steel plate, aluminum, carbon steel, copper and fiber, plastic sheeting and other non-metallic plate.

Anti-Slip Tread Plate

Made from heavy-duty steel perforated sheet, the embossed surface plays the role of anti-skid. This product can be used for building floor, industrial corridor, automotive covering, stairs, platforms decking.

Material Worked With: Stainless steel plate, galvanized sheet.

Perforated metal is punched to meshes. Holes can be round hole, square hole, rectangular hole, slot hole, triangalr hole, hexagonal hole, countersunk hole, indented hole, embossed sheets, anti-skid sheets, bridge hole, ornamental perforations. The hole shape, material, hole diameter, hole center distance, sheet thickness, sheets size and arrangement of hole can be chosen depending on applications.

Available hole shapes:

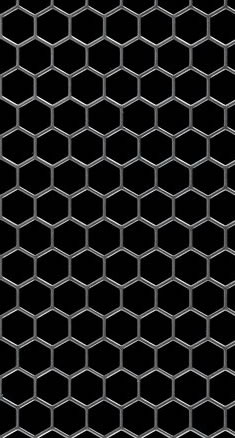

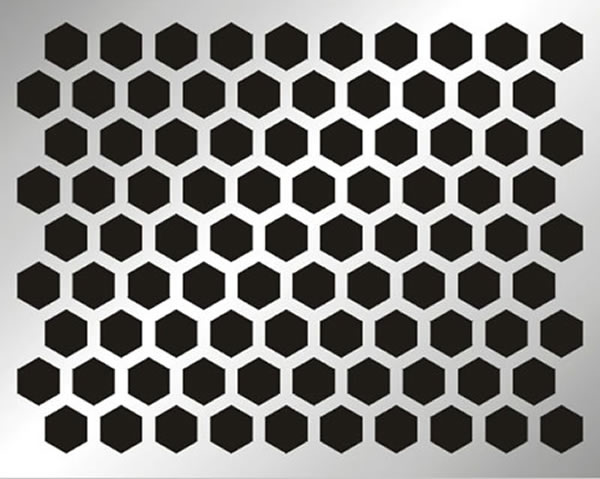

Hexagonal Opening Perforated Plate

Material worked with: Stainless steel plate, galvanized sheet, aluminum.

Triangle Opening Perforated Plate

Sheet metal materials: Steel, aluminum, stainless steel, bronze, brass, titanium, aluminum, polyethylene, and so on.

Features of Perforated Triangle Opening

Features of Perforated Triangle Opening

Good strength-to-weight ratio

Attractive appearance

Accurate hole sizes

Available in corrosion resistant materials

Available in lightweight materials

Suitable for decorative applications

Application:

Wind screen and decorative cladding sheet.

Metal Perforation is generally done by Die & Punch technique. Usually there are a number of punches and dies in a given set. The material is sheared by the sharp edges of the punch and die. The clearance (the measured distance between the outside circumference of the punch and the inner circumference of the die) must be maintained to ensure a clean cut from the work peice. The punch is pressed through the material (either by machine or hand tool) and into the die removing a blank, resulting in a perforated work peice.

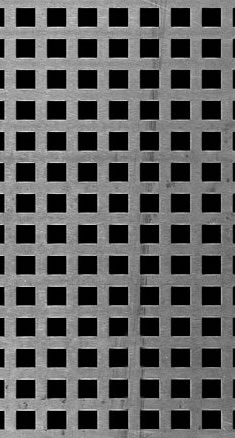

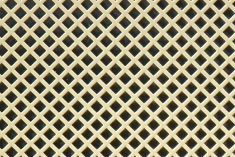

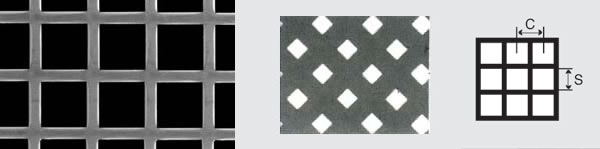

Square Opening Perforated Plate

Applications:

Machine guards

Air condition guards

Architectural curtains

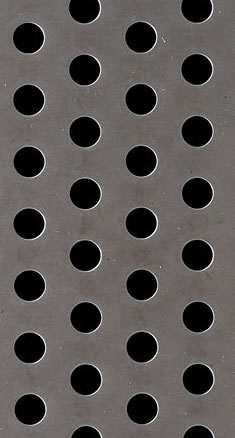

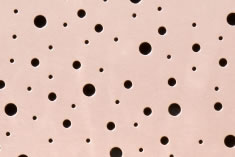

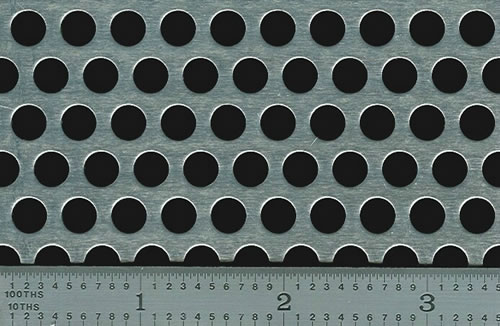

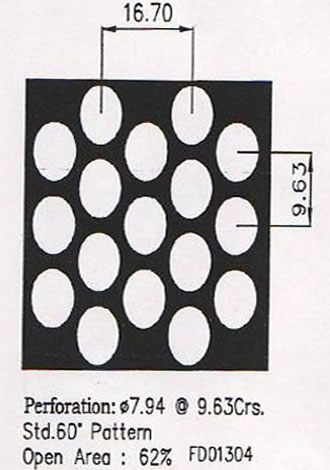

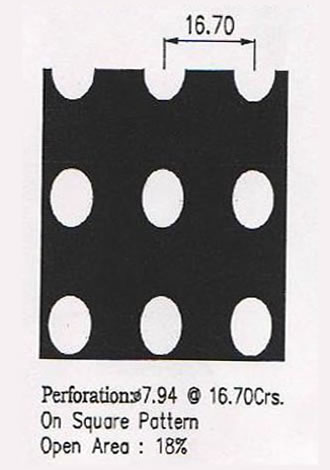

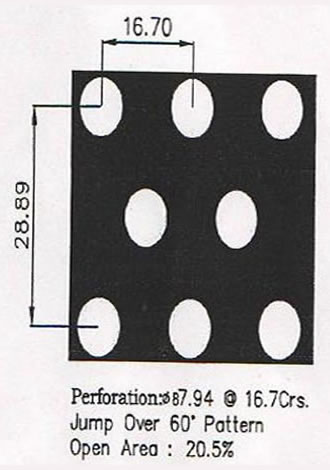

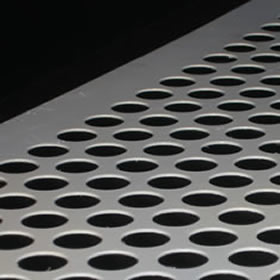

Round Opening Perforated Plate

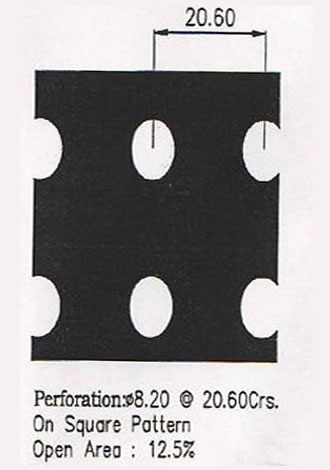

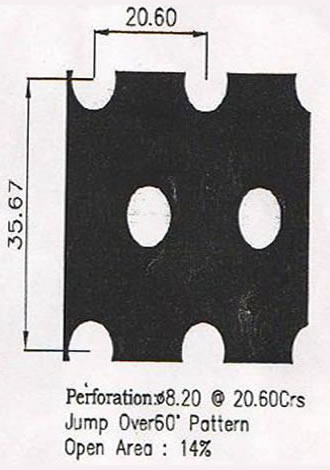

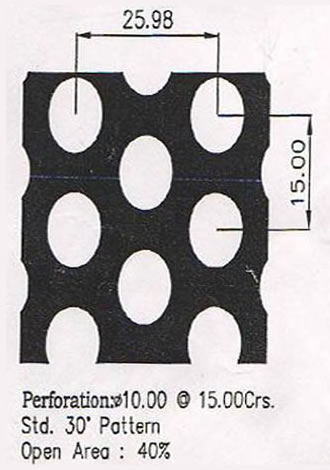

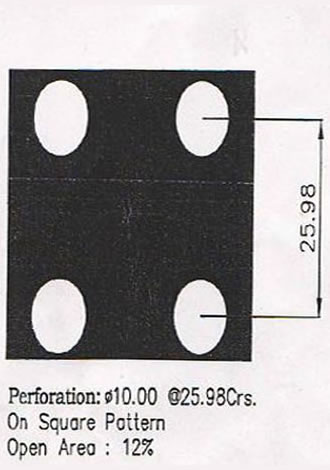

Hole size and perforation rate:

Material worked with: Stainless steel, Carbon steel, Galvanized steel, Aluminum, Brass.

Material worked with: Stainless steel, Carbon steel, Galvanized steel, Aluminum, Brass.

The hole shape: Round.

Application:

Round hole perforated metal mesh is widely used in automotive, lighting, construction, acoustical application and ornamental uses.

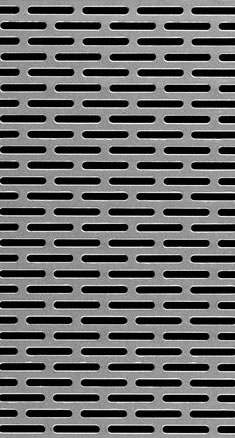

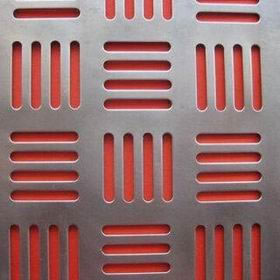

Slot / Rectangular Opening Perforated Plate

Slot / Rectangular Opening Perforated Plate

Features

Available with large percent open area

Accurate hole sizes

Available in lightweight materials

Available in corrosion resistant materials

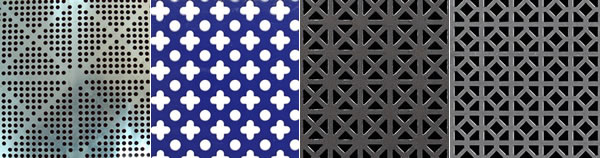

Decorative Opening Metal Meshes

Material: Hot-rolled and cold-rolled carbon steel sheets, galvanized sheets, stainless steel sheets, aluminum, aluminum-plastic, copper, nickel, titanium, PVC and other materials.

Opening: Round, oval, square, rectangular, rhombus, hexagon, scale shape combination of different shapes, also other special shape.

Process: Stamping, leveling, cutting, bending, reeling, welding, shaping and surface treatment.

Application: Decoration, construction, electronics, furniture, etc.

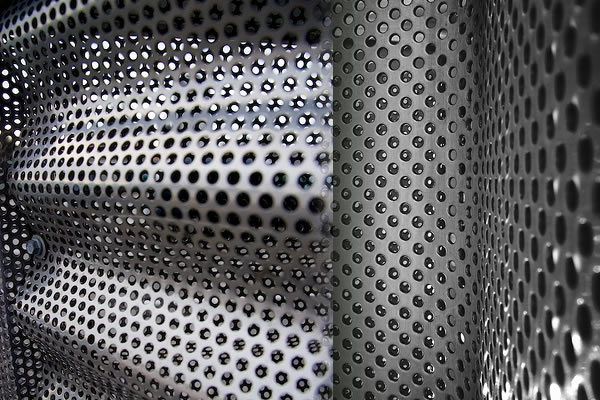

Sheet, Coil and Tubes

We provide our finished products in sheet, coil, panel, screen, or plate form. The three basic forms are sheet, coil, and tube.

SHEET

Typically produced from coil, perforated sheets can be produced in widths up to 60" and in any length (typically under 250" for shipping purposes). Supplied either fully perforated or with margins and/or blank areas, perforated sheets can be produced to meet your design and production requirements.

COIL

Ideal for original equipment manufacturers (OEMs) with automated production operations, perforated coils enable faster production by reducing handling of sheet material.

Supplied either fully perforated or as paneled sections either with or without precisely placed locator holes, perforated coil up to 60" wide can be produced in 16 gauge and thinner material to meet your design and production requirements.

Perforated Metal TUBE

Primarily used in automotive and filtration applications, perforated tubes are often subject to design requirements, stringent inspections, and competitive pricing.

Completely perforated or with blank areas, one hole size or a variety of them, straight or flared ends, perforated tubes can be made up to 6 inches in diameter and 30 inches in length in any metal type or thickness.

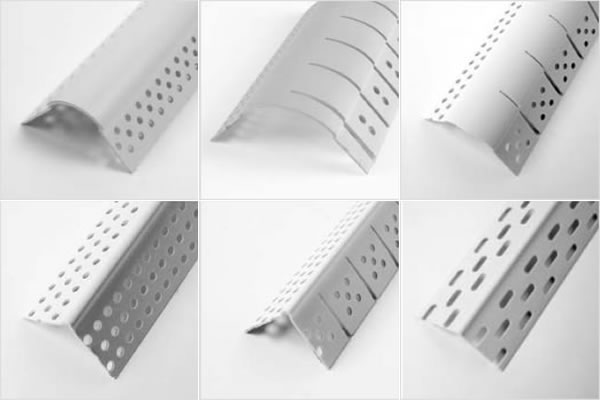

Perforated Angle Bead for Building Construction Material

Material available in plastic, galvanized steel, stainless steel.

Available in multiple lengths to help reduce waste and minimize splicing. Punching holes allow mud to penetrate through the bead to the drywall. The corner bead becomes part of the wall.

Products Center

- Woven Wire Fabric for Decoration

- Exterior Shading Screens

- Stainless Steel Decorative Wire Mesh

- Architectural Mesh Curtains

- Fireplace Curtains

- Decorative Expanded Metal

- Decorative Perforated Mesh Screen

- Architectural Facades Mesh

- Aluminium and Anodised Alu Decorative Mesh

- Decorative Gabions

- Elevator Mesh Panels

- Perforated Metal Anti-Slip Tread Plates

- Window Security Ampli Mesh

- SS304 Security Mesh

- Metal Wire Belt Conveyors

- Metal Mesh Drapery

- Gutter Mesh and Guards

- Wire Mesh Railings

- Insect Proof Mesh Netting